In order to serve the British market, STERMAN have teamed up with Rocksteady Group Limited. By bundling our competencies, we are able to respond to customer requirements in a targeted manner and deliver optimal technical solutions. Rocksteady x STERMAN stands for real added value.

Applications:

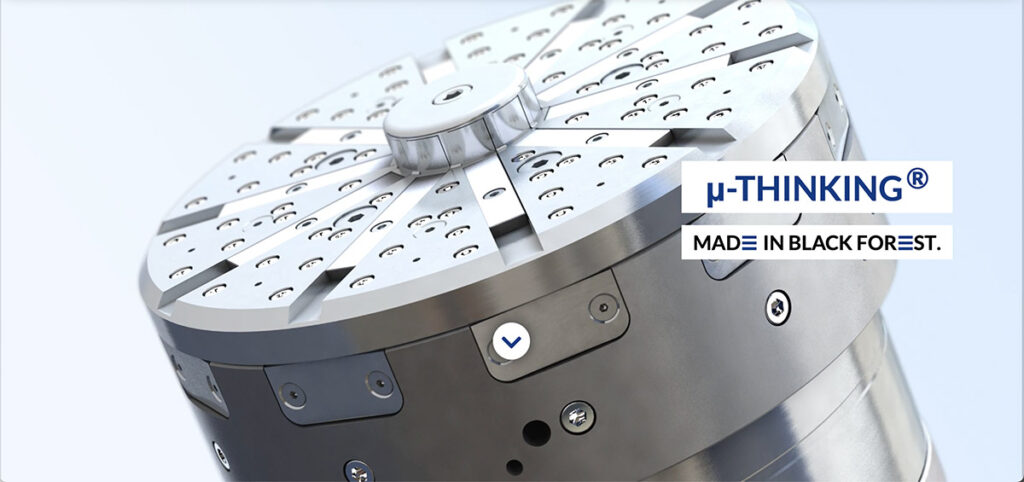

The objective always remains the same: the implementation of optimum workpiece clamping and consequently the guarantee of workpiece machining in the μ-range. We provide not only a flexible device but also a complete innovative machine concept for the individually configured clamping system and manufacture it on our premises in the Black Forest – when the challenge is highly precise machining or exact positioning for deformation-free clamping and high torque transmission.

We develop highly precise clamping technology tailored exactly to meet the requirements of your machining processes based on the specific material of the workpiece that requires processing. If required, a flexible and innovative machine concept is developed around the clamping system. We regard ourselves as partners for smart and networked product solutions in the precision class of < 0.01mm. For this purpose we ourselves develop, simulate, produce, test and maintain every single part of our technical solutions on our own premises in the Black Forest. In the course of our development work, we gladly assume the responsibility for the project as system supplier and support you as a reliable partner to ensure sustainable production throughout the entire life cycle.

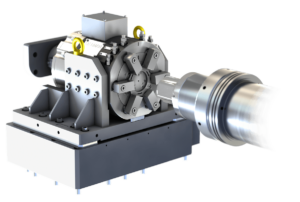

Sterman are experts in providing Clamping Systems, Devices and Mechanical Engineering. Creating customised spindle components clamping solutions to clients’ specifications.

Together we`re creating production technology for future industrial manufacturing. We are one of the leading providers of high quality special clamping technologies and systems and have equipped a large number of well-known and internationally active companies with our efficient and smart high-precision solutions for their production.

We specialise primarily in the conceptual design, development and production of clamping systems based on the individual workpiece geometry of our customers – in other words whenever the standard solutions that are available on the market do not achieve the required levels of accuracy or the desired machining processes are not possible.

“TOGETHER WE CREATE MODERN PRODUCTION TECHNOLOGY FOR THE INDUSTRIAL MANUFACTURING OF THE FUTURE.”

Johannes & Peter Sterman, managing partner of the family owned business

Engineering: Great Things Start In Detail

The μ is the mechanically smallest unit – and therefore our standard. By μ-THINKING® we mean further developing and digitally connecting clamping systems, making them more economical, more precise and future-proof. In doing so, we want to make the production technology and associated processes equally high quality and more efficient.

With the help of CAD systems and simulation programs, we develop tailor-made clamping systems and devices that meet future requirements. Working in partnership, we`re creating high-precision, efficient and innovative solutions for demanding applications of the future.

Production:

State of the art CNC turning, milling and grinding. We serve our customers from the initial concept based on the development, design and layout planning to machining production as well as throughout the lifecycle of the clamping system and manufacture the important key components with a vertical integration of more than 90% exclusively in-house.

If you’re a UK-based company that feel you can benefit from Sterman’s expertise please call or email us at Rocksteady Group and we will work alongside yourselves and Sterman to deliver your optimal solution.