Our expertise in this field is second to none. Whether you require a simple manual Dividing Head for a Old School Milling machine – or a full blown Multi Axis CNC Controlled table – we are here to help.

Our range includes high accuracy high spec tables from IRTS, and simple manual units from other manufacturers.

We are able to offer application support direct to the OEM and the Machine tool builder or importer alike.

We have handled projects with a value in excess of £100k, and our customer list includes Aerospace, Defence and Automotive companies – why not let us take a look at your application.

Our main supplier for rotary tables is ZEATS, a renowned company that been manufacturing extremely high quality Rotary Tables for 60 years from their base in Ishtar, Spain. Rocksteady Group are delighted to be able to offer their products to our customers in the U.K.

ZEATZ production facilities cover an area of 1,653 m² alongside 2 floors of offices of 210 m² each. With substantial investment made in facilities, equipment, machinery and instrumentation ands a respect for the environment, Zeats is a truly dynamic company. With an emphasis on quality of finish and design.

ZEATZ have succeeded in computerising many of the production processes, reducing delivery times as well as improving products quality, all supported by a team of highly qualified workers with extensive experience in the ZEATZ product.

Horizontal Rotating Tables

The family of Standard Horizontal Rotary Tables of the PH family designed and manufactured by ZEATZ can be configured in three different ways, either round, square or rectangular, in addition to different groove measurements according to the needs of the client and their applications.

Two configurations of Rotary Tables or Rotating Plates are manufactured according to the type of rotation drive:

Horizontal & Vertical Rotary Tables

The Horizontal and Vertical Rotary Tables of the PHV Family designed and manufactured by ZEATZ are specially designed to be able to work vertically or horizontally, thus acquiring great versatility when it comes to making any type of part.

Dimensions:

The dimensions of the Horizontal and Vertical Rotary Tables range from 320 mm to 3000 mm.

Structure:

The design of these Rotary Tables specially reinforced both in their structure and in their elements allow to perform works of great power and precision either working in the air or with supports such as tailstocks, lunettes, rollers…

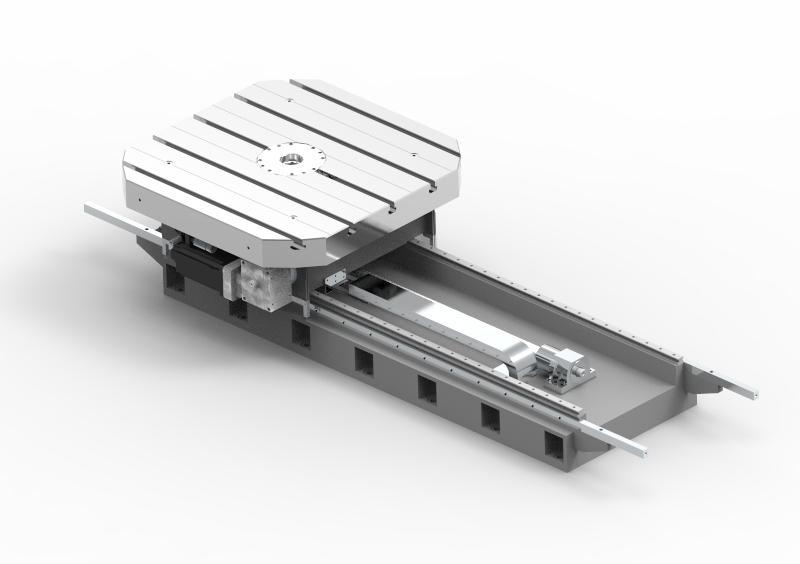

Linear Rotary Tables

The courses of the Linear Rotary Tables can range from 1 meter to 12 meters in the larger versions.

The table drive is usually ball screw in short versions and rack and pinion with anti-slack system in which they require more travel.

The positioning measurement system is by means of optical rules to ensure accurate positioning in all working conditions.

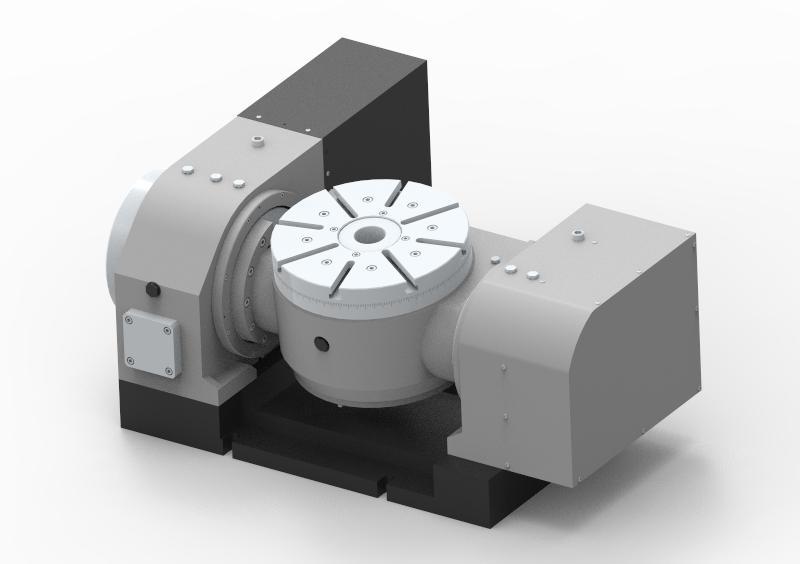

Rotating Tables Tilting

Since 1962 ZEATZ have manufactured Rotary Tables with continuous tilt and turn , that is, Tilting Rotary Tables.

Rotary tables with automatic tilt angle offer great versatility when facing any job as complicated and demanding as it is.

For this they are designed so that each axis has its drive, its locking system and its measuring system.

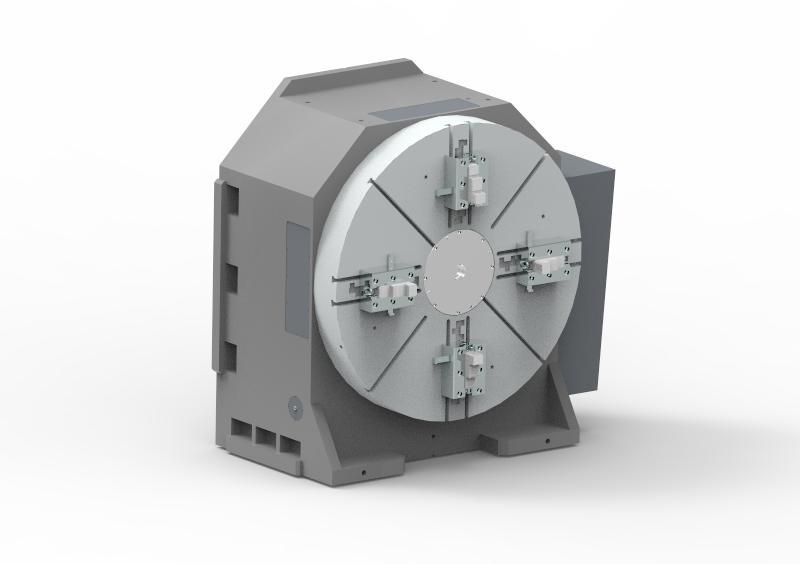

Rotating Tables For Milling, Turning & Rectified

The family of Rotary Tables for Milling and Turning of the PHT Family designed and manufactured by ZEATZ.

They offer us the possibility of carrying out more than one process to the pieces to be machined. For this we offer the option to configure our splitter with mechanical or direct motor transmission.

In the wide range that ZEATZ manufactures we have the option of configuring the Rotary Tables with the necessary benefits for each case such as: No. of revolutions, power, horizontal or vertical axis, etc.

The tables can also be equipped with hydraulic outlets of 4, 6, 8, 10 … points to adapt any type of automatic mooring piece or palatization.

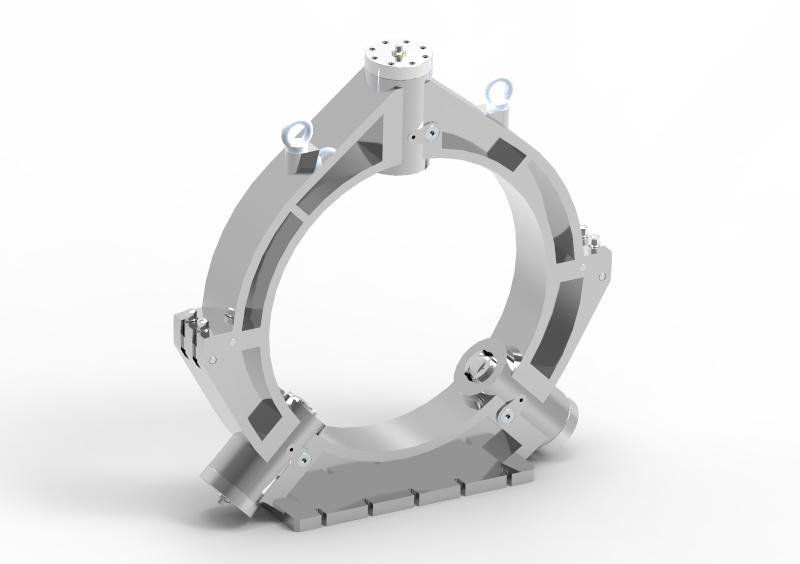

Steady Rest Accessory for Dividing Plates & Rotating Tables

The size of the Steady Rest will depend on the load capacity and dimension required for each client.

The Steady Rest can be opened or closed, of 2,3 or 4 points and their displacement will depend on the type of pieces that have to tie.

SUPPORT MOUNTS WITH ROLLERS:

Each roller has linear displacement to adapt to different dimensions.

The fixed pneumatic windows have bronze bushings to fit different part diameters.

The manufacture of large windows and their adaptation to the bench.

Steady Rest Accessory for Dividing Plates & Rotating Tables

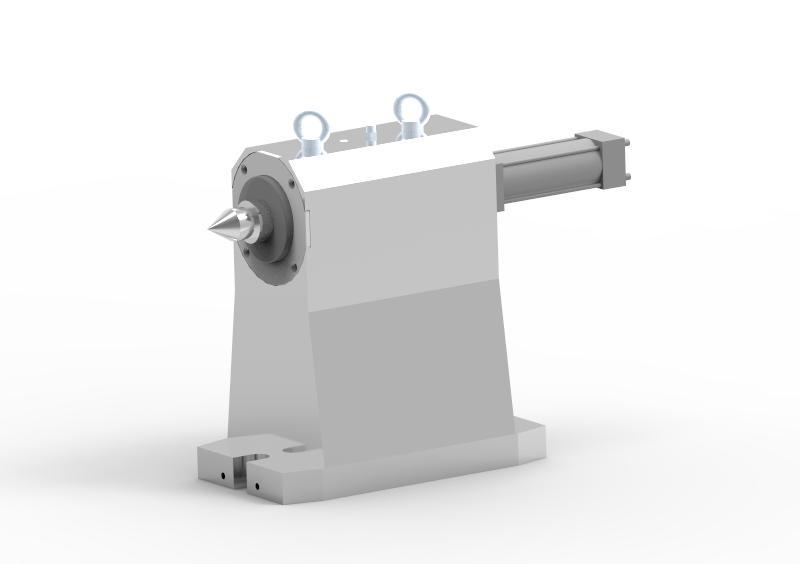

The Tailstock CP of ZEATZ is one of the most important accessories of a Divider Plate.

ZEATZ manufacture all types of tailstocks: automatic, pneumatic and manual.

ZEATZ can manufacture tailstocks of any size, adapted to the needs of the client.

In special projects the counterpoint can have linear displacement by means of a zipper.

QUALITY CONTROL OF OUR PRODUCTS

All of ZEATZ’s Rotary Tables and Rotary Tables are verified during the manufacturing process. Once verified, each product is delivered with the corresponding Verification Data Sheets, both for geometry and angular verification.

Angular verifications are performed in our laboratory by means of a Renishaw Interferometric Laser System with which we measure angularity, positioning, straightness, etc.

ZEATZ can perform these verifications on all types of machine tools both at our facilities and at the customer’s facilities.

VERIFICATION AND COMPLIANCE STANDARDS:

ZEATZ subject all Rotary Tables and Rotary Tables to detailed and accurate tests that certify compliance with the following standards:

LABORATORY

The company has a Verification Room of 150 m² with which we carry out all the detailed and precise verifications, which certify compliance with the following standards: UNE 15300-2, UNE 15450-2 and VDI/DGQ 3441.