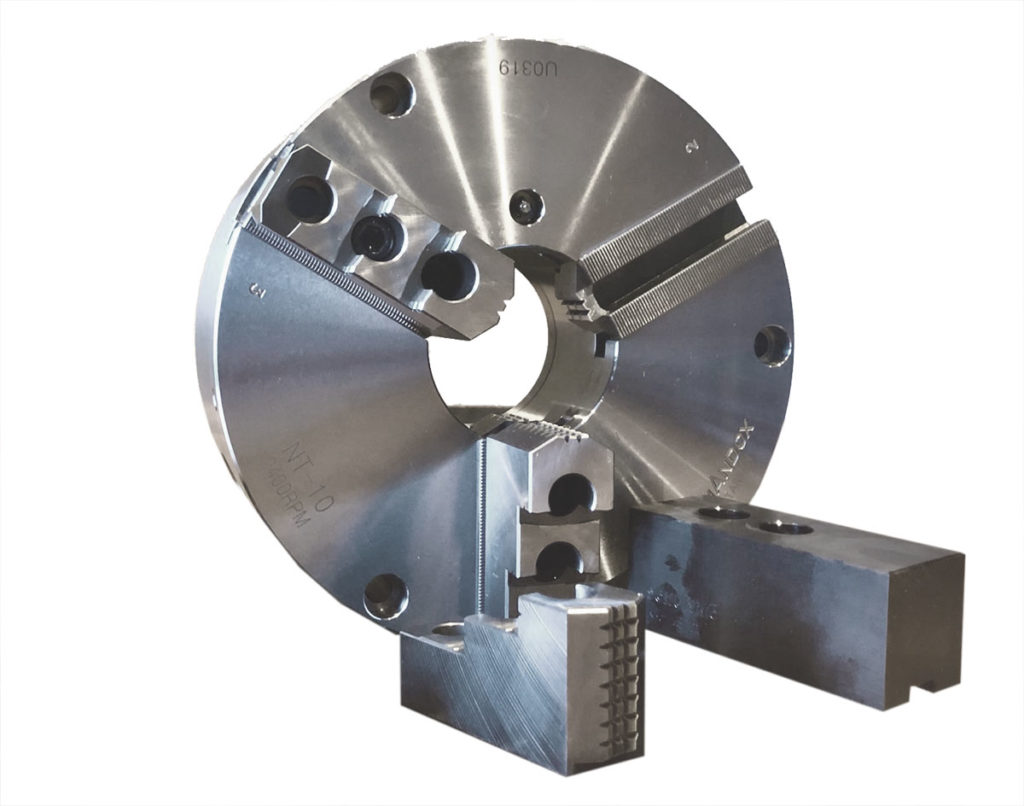

FOR OVER 10 YEARS, THE COMPANY HAS ADDED TO ITS HISTORICAL PRODUCTION OF SELF-CENTRING CHUCKS FOR LATHES

This last task involved the investments made in recent years in terms of machinery and equipment and specialists.

Omap is able to provide machined parts working them, at all stages, within its facility. The pieces can be subjected to all the required machining: milling, turning, plunge and wire spark cutting, internal, external, tangential and planetary grinding before being subjected to final testing with the most modern means of control.

The policy of Omap and technical features of the workshop allow the customer to request small batches (1 to 100 pieces). The urgency is an important parameter and that is why Omap is always ready to change its processing to meet customer needs. It also has a large stock of steels to meet all your needs quickly.